MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability

crusher plant biaya instalasi di india jspfoundation. biaya investasi pabrik stone ... feeding of fly ash to lafarge cement mills of sonadih ... Untuk Produksi Semen ... Dapatkan harga

This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder. This is achieved in a cement raw mill.

CHAENG can provide various types of vertical cement mills with productivity of 50250t/h. The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical mill. GRMK vertical cement mill has the advantages of compact structure and small volume.

Genevieve cement plant, which is among the most advanced cement plants of its kind. The stateoftheart plant's single kiln is 300 feet long by 21 feet in diameter. It has a production capacity of 12,000 tons of clinker (a cement product phase) per day, making it the largest single clinker production line in the world.

Competence for the processes in the Cement Industry. 6. The Cement Industry typically produces Portland cement – sometimes also masonry cement. Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of .

mini cement plant grinding machinary mt perday Oject Cost Mini Cement Mill In India brsin, Mini Cement mini cement mill 50 tons per day, clinker grinding unit crusher company Price 100 mt, Machinery Abstract: 50 Tpd Mini Cement Plant .

Roanoke Cement Company LLC Roanoke Cement and its employees are committed to being good neighbors in the community and careful stewards of the environment. The only active cement plant in the Commonwealth of ia, Roanoke Cement is an Energy Star® Partner and the recipient of multiple of environmental, industry and safety awards.

Cement manufacturing is an energy intensive process because raw materials must be dried and heated to temperatures of about 1400 °C to initiate the chemical reaction that produces cement clinker. Kiln technologie The core technology of a cement plant is the cement kiln (Fig. 2). This is the area where investment costs are high

GCC's Type V cement is typically used where concrete will be in contact with soils or groundwater containing high sulfate levels or in structures where concrete will be exposed to sulfates. Find Mill Certs for this cement type here. Rapid City, SD Plant. Pueblo, .

vertical raw mill cement plant jeveuxduvinbe. vertical Roller mill | LNV Technology Pvt Ltd Vertical roller mills are large grinding machines developed, designed and, A vertical raw mill is mainly used in cement plants for raw, [24/7 online] Cement Plant Raw Mill Penta Engineering Corporation

Bihar Cement Plant (A unit of Shree Cement Ltd.), Aurangabad 3. Kalyanpur Cements Ltd 4. New Bihar Cement Plant (A unit of Shree Cement Ltd.), Aurangabad 5. SHIVAY CEMENT PVT LTD 6.

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

Jul 21, 2014· Siam Cement Group's Moulmein Cement Plant In Burma (Compilation of news articles direct from the GLOBAL CEMENT NEWS in March 2014.) Myanmar: Thailand's Siam Cement Group (SCG) aims to produce nearly 2Mt/yr of c e ment at its new plant in Myanmar once the US400m plant .

Mar 29, 2017· Primarily for cement grinding plants in India, coal (generally of bituminous grade) is used in the slagdryer. The wet slag arrives at the stack on wagons from some nearby steel plant, or it may be brought via a trolleysystem (primitive mode).

In a dry kiln cement plant, electricity use is typically broken down as follows (ECRA, 2009): 38% cement grinding, 24% raw material grinding, 22% clinker production including grinding of solid fuels, 6% raw material homogenization, 5% raw material extraction, and 5% conveying and packaging.

AGICO is specialized in design and supply equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD,main equipments:Rotary Kiln, .

cement plant equipments manufacturer and suppliers of, Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production...

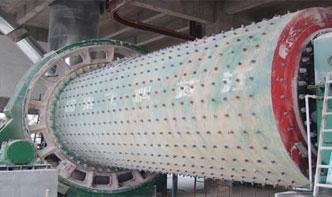

In Kuwait, Intercem constructed a complete cement mill plant on the basis of a used and reconditioned raw mill with a diameter of m and a length of 13 m. The ball mill has a double pinion drive with an output of 2 x 1750 kW. The mechanics were enhanced and rounded off with entirely new electrics and automation equipment.

Process control optimization of rotary kiln line, raw mill and coal mill at the Adana cement plant in Turkey 20% decrease in standard deviation, 10% longer refractory life, .

Dec 01, 2017· 3) The cement mill grinds the clinkers to an appropriate heat to produce cement. Each step is critical but the final step is where the magic happens. Grinding to perfection. In the final step, the cement mill grinds the clinkers using horizontal ball mills. The ball mill has two rotating chambers with ceramic balls that grind the clinkers.

A VSK Mini Cement Plant is smaller in size as compare to a normal Rotary Kiln Cement Plant. VSK Cement Plant is known for occupying less space, high production capacity and feasibility. We are counted among the distinguished VSK Cement Plants manufacturers and exporters based in India.

Raw Mill In Cement Plant () China Zk China Zk Share. Supplier From China Jun1017 . Company Products Raw mill is mainly used for grinding cement raw materials. It can also be used for grinding various ores and other materials in electric power, metallurgy, chemical industry and other industry. ...

إذا كنت مهتما في شركتنا أو المنتجات، ترحيب لزيارة شركتنا أو المكاتب المحلية. يمكنك أيضا الحصول على الاتصال معنا من خلال الاستشارات عبر الإنترنت، وتقديم الطلب الجدول، والبريد الإلكتروني والهواتف. موظفينا يجب بكل إخلاص تقديم معلومات المنتج، تطبيق المعرفة و خدمة جيدة بالنسبة لك.

Copyright © .CNمحطم All rights reserved.Sitemap